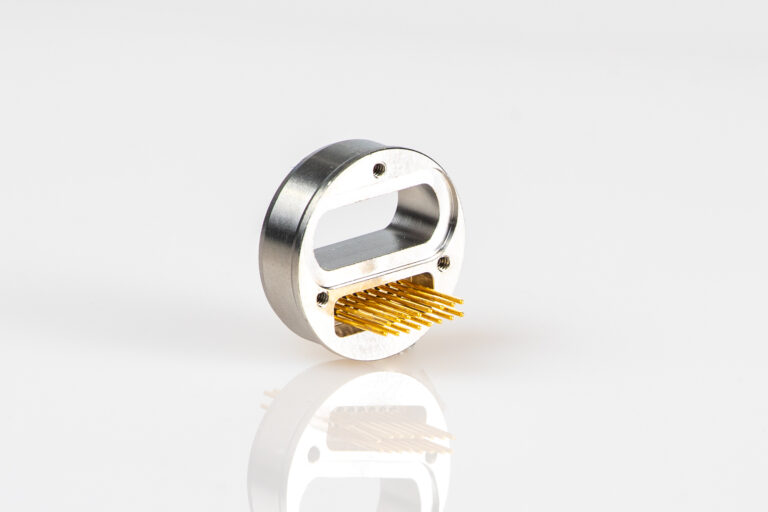

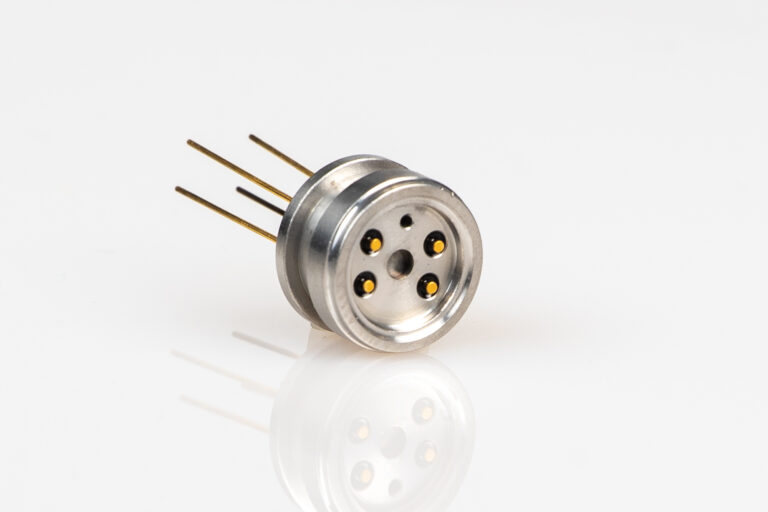

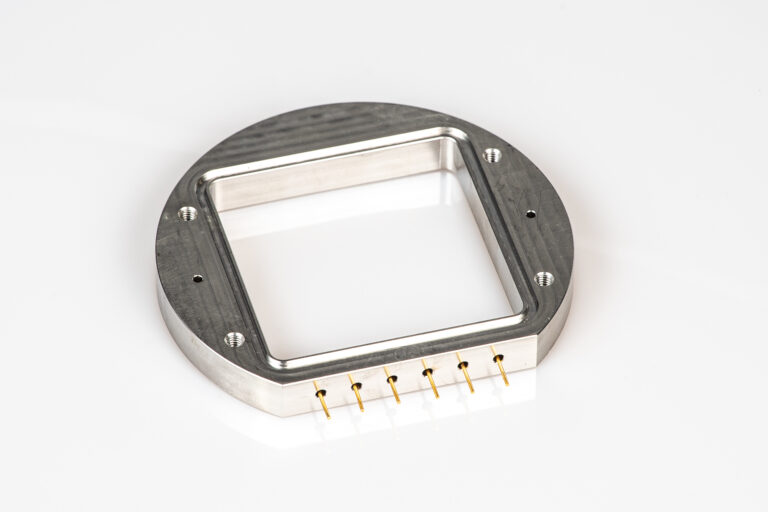

Glass feedthroughs

Bolt feedthroughs – Electrical feedthroughs – Adapted glass feedthroughs

Understand Develop Produce

Custom-designed electrical feedthroughs for conducting currents and signals through different media/atmospheres

EXPERIENCED SPECIALIST ENGINEERS

DEVELOPING

MORE THAN JUST DELIVERY

A special glass feedthrough, also called a bolt feedthrough, current feedthrough, flange feedthrough and cable feedthrough, which usually consists of a pressure body, the contact pin(s) and the glass body (insulator), can be individually designed depending on the intended use.

It can be integrated into complex technical structures, such as measuring heads or sensors, through soldering, bonding, welding or screwing, depending on the application. The processing of highly refined steels and novel materials such as titanium and tantalum is just as much part of our services as the use of technical glass and high-performance ceramics. In-house surface finishing of the contact pins and/or the outer surfaces of special glass feedthroughs facilitates contact through soldering, plugging or bonding.

- In-house electroplating

- Gold plating (fine gold, hard gold, chemical gold)

- Assembly tailored to customer requirements

- X-ray fluorescence analysis (in-house radiation protection officer)

- Leakage measurement, pressure test, roughness test

- Corrosion measurement

- Insulation resistance test

- Layer thickness measurement

Technical specifications

The following parameters can be achieved with a glass feedthrough according to the current state of the art:

- Outer diameter 3…150 mm

- High temperature resistance > 450 °C

- High pressure load capacity > 4500 bar

- High chemical resistance

- Absolute gas tightness 1 * 10-9 mbar l / s

- High dielectric strength > 4 kV

- High electrical Riso > 1 TΩ

Contact person